1. Brief introduction of WESP wet electrostatic precipitator:

The wet electrostatic precipitator is usually set in the wet desulphurization device. After the desulphurization, a large number of water droplets are carried in the saturated flue gas, which can be captured in the high voltage electric field, which can reduce the formation probability of the gypsum rain. At the same time, for collecting fine particles PM2.5, acid mist and so on, the smoke concentration can reach less than 5 mg / m3.

Two, WESP wet electrostatic precipitator advantages:

1. The dust collection performance is not related to the dust characteristics. It can be effectively collected for the viscous or high specific resistance dust, and is also suitable for the treatment of high temperature and high humidity smoke, and the possibility of ignition and explosion will be reduced to a minimum. The filtration efficiency is more than 95%.

2, there is no two dust emission, the dust concentration of export can be less than 50mg/Nm3;

3, because there is no rotating parts such as hammering equipment, the reliability is high.

4. It can effectively collect sulphuric acid aerosol and sub micron particles in flue gas.

5, the structure is simple, the layout is reasonable, the operation is convenient, the floor area is small, the internal anticorrosion adopts the acid resistant and wear-resistant adhesive mud lining technology, the chemical stability is strong, the thermal stability is good, and the service life is long.

6, there are three dehydrators in the dust collector, and the gas and water are separated thoroughly and thoroughly. Dust removal and desulfurization are synchronous, no scaling and clogging problems, washing water is recycled, and operation cost is low.

7, the efficiency of removing fine particles is high, but it needs better dispersion of liquid phase and larger power consumption.

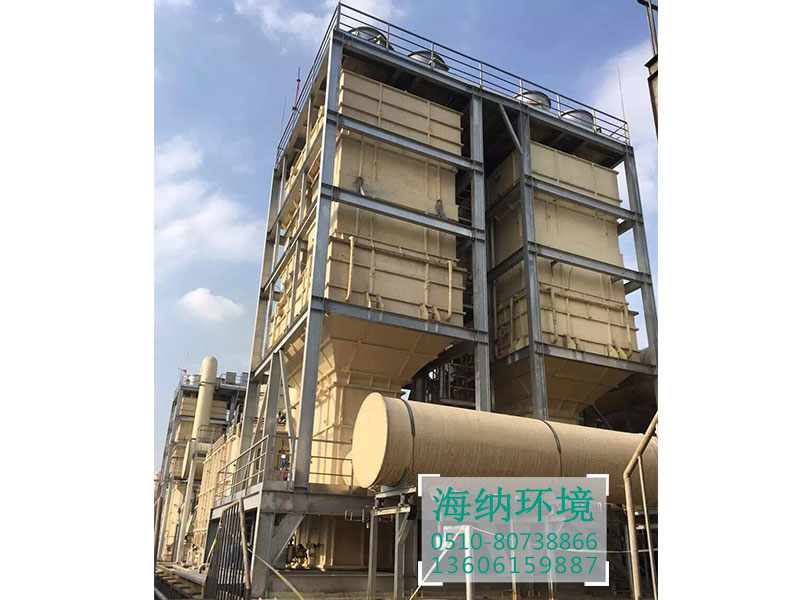

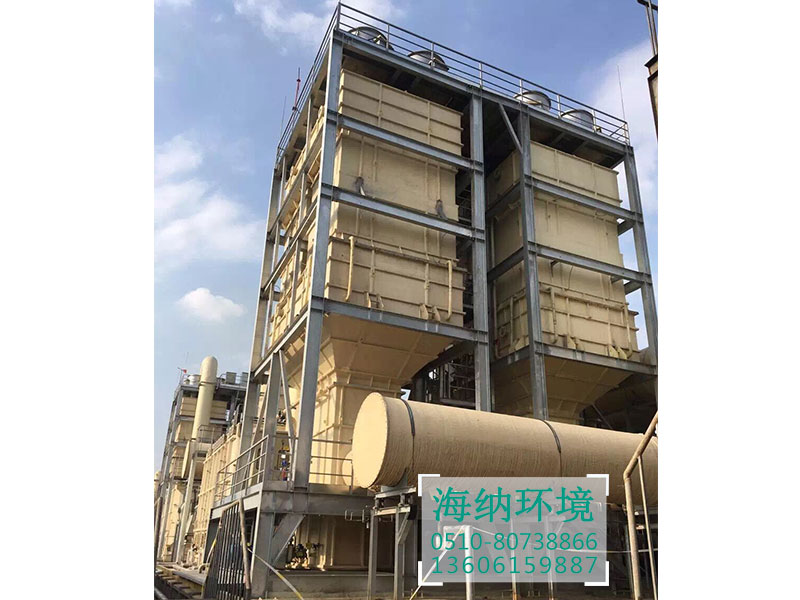

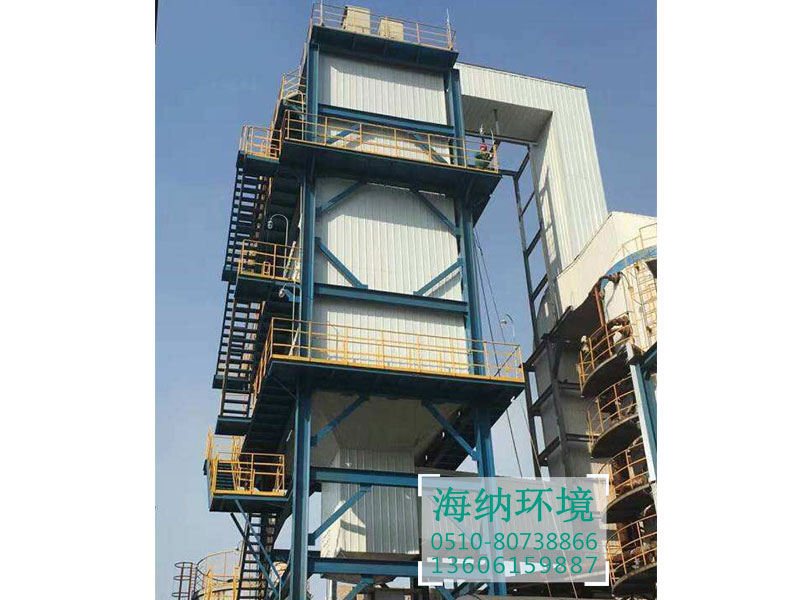

The main structure of three and WESP wet electrostatic precipitator

Bottom intake chamber - lower box (internal airflow board) - anode module (internal tangential 360, 300 honeycomb conductive glass tube bundle) - cathode system (cathode wire, heavy hammer) - upper box (cathode frame, backwash spray) - high pressure crossflow power supply

The wet electrostatic precipitator mainly selects the honeycomb conductive glass tube to produce and design the equipment. Compared with the circular tube wet electrostatic precipitator, the honeycomb tube wet electrostatic precipitator and the circular tube type wet electrostatic precipitator are the same space or the same size dust collector. The honeycomb tube wet electrostatic precipitator has a larger dust collecting area, and the same reason its dust removal ability is stronger.

Four and WESP wet electrostatic precipitator layout

The system resistance of the wet electrostatic precipitator can be installed at the top of the desulfurization absorption tower (and can be installed in the rear of the desulfurization absorption tower); the honeycomb conductive glass tube flushing wastewater is directly used in the desulfurization absorption tower to be recycled without extra treatment.