1. The working principle of low pressure long bag pulse precipitator.

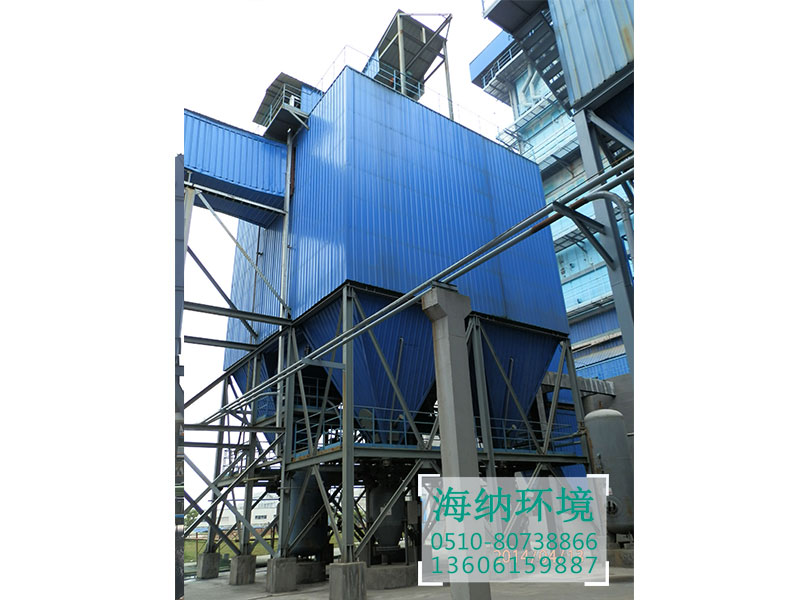

The dust remover is made up of ash hopper, upper box, middle box and lower box. The upper, middle and lower boxes are divided into chambers.

The dust gas is entered into the ash bucket from the inlet duct. The coarse dust particles fall directly into the bottom of the ash bucket. The fine dust particles enter the middle and lower boxes with the turning point of the air flow. The dust is attached to the outer surface of the filter bag. The filtered gas enters the upper box to the net gas collection pipe row air duct and is discharged to the atmosphere by the exhaust fan. The dust removal process is to cut off the net gas outlet duct of the room first, so that the cloth bag in the room is in the state of no airflow.

Then the pulse valve is opened with the compressed air for pulsing dust cleaning, and the shut-off time of the shut-off valve is sufficient to ensure that the dust removed from the filter bag is settled to the ash bucket after the injection, and the phenomenon that the dust is attached to the surface of the adjacent filter bag after the surface of the filter bag is attached to the surface of the filter bag is avoided, so that the filter bag is cleaned thoroughly and the programmable controller is used. The exhaust valve, pulse valve and ash unloading valve are fully controlled.

Two. Performance characteristics of long bag off-line pulse duster:

1. Using pulse injection cleaning technology, it has strong cleaning ability, high dust removal efficiency, low emission concentration, small air leakage rate, less energy consumption, less steel consumption, less area, stable and reliable operation, and good economic benefit. It is suitable for flue gas dedusting in metallurgy, building materials, machinery, chemical industry, power industry and light industry.

2. The box is designed with tightness, good sealing performance, good sealing material for inspection door, leak detection with kerosene in production process, and low leakage rate.

3. Inlet and outlet air duct is compact and airflow resistance is small.

4, the use of split air pulse injection cleaning, ash removal cycle long, low consumption, can double the service life of filter bags and valves.

5, the machine can be replaced without stopping, and maintenance will not affect the normal operation of the equipment.

6. Using the upper bag pumping method, the working mechanism of the bag filter is improved by the filter material, the dust particles are filtered and the filter materials collect the coarse particles mainly by the inertia impact, and the fine particle dust mainly depends on the diffusion and sieving effect.