Single machine pulse deduster

Our company's warehouse top dust collector adopts high pressure and large flow pulse valve, and filters the bag into the dust. It is used in the top of the warehouse, the top of the storehouse, the top of the tank and other parts, which can be used to filter the industrial dust carried by the gas to avoid the air dust, and to recover the usable dust in the industry of building materials, metallurgy, mine, chemical, coal, non-metallic ore and so on, and avoid the loss.

The dust gas is entered by the air intake and enters the filter bag through the open flange. The dust gas is filtered into the net gas chamber through the filter bag, and then through the exhaust port of the air cleaning chamber, the fan is discharged by the fan. Dust is attached to the outer surface of the filter bag and increases continuously, making the resistance of the bag filter rising constantly. In order to prevent the excessive resistance of the equipment, the dust on the filter bag should be cleaned regularly.

Ash cleaning is an artery punching valve in the regular sequence of the program controller, which causes the compressed air (0.5~0.7MPa) to be ejected from the hole of the blowpipe and inducted several times the air around the first wind (called the two wind), entering a filter bag to make a rapid expansion of the filter bag and shaking the dust from the reverse direction of the air flow, and the dust attached to the bag table quickly. Leave the filter bag back to the warehouse / tank / tank.

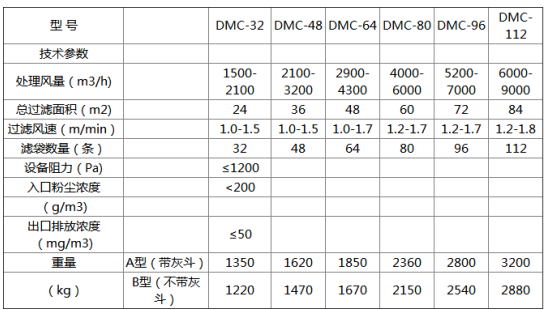

Four, equipment selection

A type: a single machine pulse bag filter

B type: for the top dust collector